- Home

- Thyristor Power Controller

- REVO RT - 3-zone PID power controller up to 90A

| Monophase Channels: | 3 |

| Triphase Channels: | 0 |

| Type: | Power controller |

| Current range: | 35A-90A |

| Max Voltage: | 480V, 600V |

| Communication: | Modbus |

| Approvals: | CE / UKCA |

| Load: | Resistive |

| Thermoregulation: | Integratrd |

| Energy Management: | Yes |

- General Details

- Code / Size

- Software

- Documentation

REVO RT

3-zone PID power controller up to 90A

The REVO RT is a compact power controller unit, which integrates a single phase static unit for each loop for electrical power management.

Each unit manages 3 independent control loops. The unit can be purchased with the diagnostic functions for the load and for the SCRs. In this case there is a amperometric transformer for each channel.

Each power channel is always equipped with extra rapid fuses.

The standard incorporation of power, CTs and fuses into a single unit saves considerable space and wiring time.

Available in the following currents: 35, 50, 75 and 90A with maximum voltages 480V and 600V.

- REVO RT two zones up to 35A is normally used for packaging machinery.

- REVO RT three zones up to 50A is normally used for plastics machinery.

- REVO RT up to 90A is normally used in Furnaces.

Cutting wires and compact electric panels to cut costs

Have you ever considered the influence of wiring and installation labour costs on the total cost of your project? Well, we propose to halve these costs:

Eliminating wires to be: cut, stripped, numbered, connected, panels to be drilled…

These are all time-consuming operations that greatly affect the final cost. REVO RT saves up to two hours of wiring per temperature control zone.

Save time, money and space:

- REVO RT is an easy-to-install modular multi-zone system that ensures simple maintenance.

- The LEDs on the front of the unit make it easy to detect a fault and replace the unit.

- This can be done even by non-specialised personnel.

With REVO RT you can save working time per zone compared to a system based on discrete controllers. This saving is achieved by considerably reducing the wiring of each zone and the time required for:

- Reading and understanding diagrams.

- Measuring distances.

- Cutting wires.

- Marking and insertion of terminals.

- Panel drilling.

By calculating material costs, hourly labour costs and how many zones are wired in a year, you can immediately calculate the savings the REVO RT system can bring to your organisation.

Furthermore, with the REVO RT system you can drastically reduce the size of your control panels, saving several hundred euros.

Why the modularity 3 is better than 4?

CD Automation wants to propose an approach that focuses designers on the need to better balance the loads on the three phases. When it is possible, it is always better to balance the three phases. This is often difficult with a modularity 4 or 8 zones, which push the designer not to balance the three phases to avoid adding other modules that are underused.

For those applications that necessarily have to use four zones, CD Automation also offers the RT2 two thermoregulation zone model, which has an additional input that can be used for a safety measurement or for measuring the Melt pressure in extruders for plastic materials.

Synchronization, with a 3 zone single phase unit, can be achieved with extreme precision:

The ECO function distributes the power during regulation (<33%) in the set cycle time, this help to avoid all the three loops demanding max power output at the same time. The microprocessor provides a series of configuration and diagnostic parameters, including the current absorbed by the loads, the operating status of the zones, the situation of the alarms, etc.

Microprocessor – Special functions

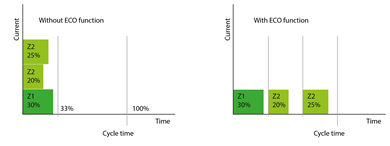

ECO function

The ECO function distributes the power during regulation (< 33%) in the set cycle time.

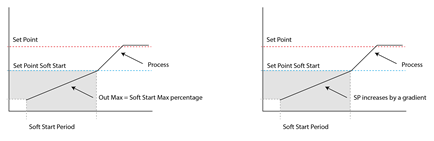

Soft Start

To avoid thermal shocks to the heating parts, it limits the output power in a certain period of time, or makes a ramp to the set point when the regulation is activated.

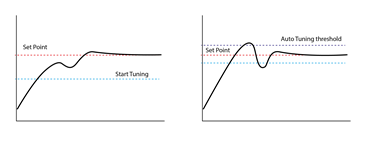

Auto Tuning

Automatic calculation of the Tuning parameters, with mode adaptive or single.

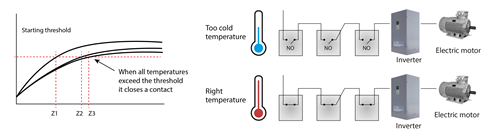

Ready to Go

When all temperatures reach a predefined absolute threshold, a contact is closed to enable the extruder to start.

Ready for Industry 4.0

The choice of Modbus RTU as standard communication protocol on the unit is due to the great ease of interfacing with HMI operator panels, PLCs, industrial PCs and other units present on the system which in most cases are already equipped with this communication standard.

Through the use of the TU-RS termination unit it is possible to connect the REVO RT with some of the most common field buses on systems including PROFINET, PROFIBUS DP, EtherNet/IP™, Modbus TCP.

The unit is plug and play because it is configured by us according to the specific needs of each customer.

Technical specification

Controller Module

- PID temperature controller with Pre Tune, Self Tune and Manual tuning

- Up to three Heating Only or Heating and Cooling PID Loops

- RS485 communication from 19200 to 57600 Baud Modbus RTU protocol.

- Auto/Manual bump less balances.

- Configurable input for Thermocouples and linear Signal.

- Five configurable Relay outputs for Alarm, Cooling output or Motor Start Enable.

Thyristor Module

- Solid State Relay 35, 50, 75 or 90A

- 480V or 600V Max

- Integrated Extrarapid Fuses

- Integrated Current Transformer with Heater Break Alarm Option

- Heatsink + Fan

- Panel Mounting

- Indication LED

Simple and intuitive configuration

The unit is configured through a USB port on the front of the instrument and a very simple and intuitive software through which it is also possible to record and download standard configurations.

Configuration Software for REVO RT:

| FILE NAME | DESCRIPTION | Link |

|---|---|---|

| Thyristor Configurator 6.0.6.4 | Thyristor Configurator Software REVEX 1/2/3PH, REVEX PA, REVO C 1/2/3PH, REVO PC v2, REVO PN v2, REVO PB, REVO RT/RTL, COMPACT, REVO TH |

The all new powerful Thyristor Configurator Software allows you to configure all CD Automation products quickly and easily by using the FAST MODE. Simply select your application and the load type picture appears automatically, providing a list of suggested parameter settings. Depending on your application requirements, you can accept or make manual adjustments and when ready, download direct to the thyristor unit.

The TEST page is very useful when installing & commissioning

CD Automation products as well as finding process issues or fine tuning at a later stage. You can read, write, enable and disable key values and parameters to test your load. Examples include; reading voltage, current and power values, or current limit status, changing input types between analog or SSR, control (feedback) modes V, I and VxI, or select firing types half cycle, single cycle, burst firing, delayed triggering, phase angle and soft start. The new ‘Load Analyzer’ (a small oscilloscope) can be activated from this page, see below.

Provides real-time information of the output waveform, where

you can select up to 10 process variables to help the operator determine if the waveform is in line with process expectations. Also useful for trouble shooting.