Infrared lamps:

In the field of industrial heating, infrared lamps play a crucial role. CD Automation, a leader in the automation sector, offers state-of-the-art solutions to optimise the use of these lamps. Our thyristor units for handling infrared emitters are designed to ensure precise and reliable power control, essential for a wide range of applications.

- Read more

By using our power controllers, companies can not only improve process efficiency, but also reduce operating costs and environmental impact. CD Automation’s solutions for infrared lamps offer unparalleled power management, ensuring optimal performance and longer lamp life. Rely on CD Automation for advanced and sustainable management of your infrared lamps.

Infrared lamps: select your load connection

To get the most out of infrared lamps, choosing the right connection is crucial. CD Automation guides you in making the ideal selection, ensuring optimal performance of your machinery and reliability over time.

Medium- and long-wave infrared lamps

Medium-wave and long-wave IR emitters behave as normal resistors. If medium waves are used at a voltage value below the nominal value, they are treated as if they were short-wave loads.

Short-wave infrared lamps

With short-wave IR lamps, and in particular ultra-short-wave IR lamps, special care must be taken when choosing the junction used inside the thyristor unit. Indeed, when switched on, such lamps cause current peaks of 16 times the nominal current

Infrared Short Wave loads can be driven with different types of Firing: Single Cycle, Burst Firing and Phase Angle with Current Limit.

Learn more about CD Automation’s solutions for managing infrared emitters

In the area of industrial applications using infrared lamps, CD Automation offers a number of specific solutions to suit different IR emitters configurations. Understanding these configurations, together with the features of product families such as REVO PC, REVO S, REVO PN, REVO C, REVEX and REVO TH, highlights the company’s customised and technologically advanced approach.

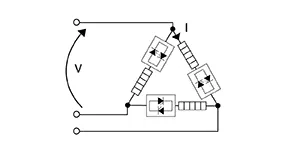

For IRSW 1PH (single phase) lamps, products such as REVO S and REVEX are particularly suitable. These devices offer precise power control, which is essential for the optimal operation of single-phase short-wave infrared lamps, ensuring even and efficient heating.

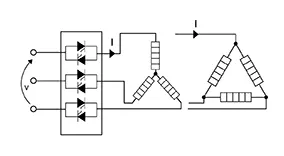

In the case of IRSW lamps in Delta/Star configuration without Neutral, power controllers such as REVO C and REVEX PA become indispensable tools. These systems are designed to effectively manage IR lamps in complex configurations, providing reliable and precise control of heating.

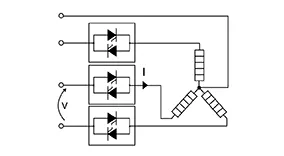

For short-wave IR lamps Star + Neutral configuration, the products of the REVEX family are just some of the proposals available. These controllers can precisely manage IR lamps in this specific configuration, ensuring the best performance and reliability over time.

Finally, for short-wave IR lamps in Open Delta configuration, systems such as REVO C and REVEX single-phase are particularly effective. These devices can handle various loads and adapt to different configurations, ensuring optimal control of IR lamps.

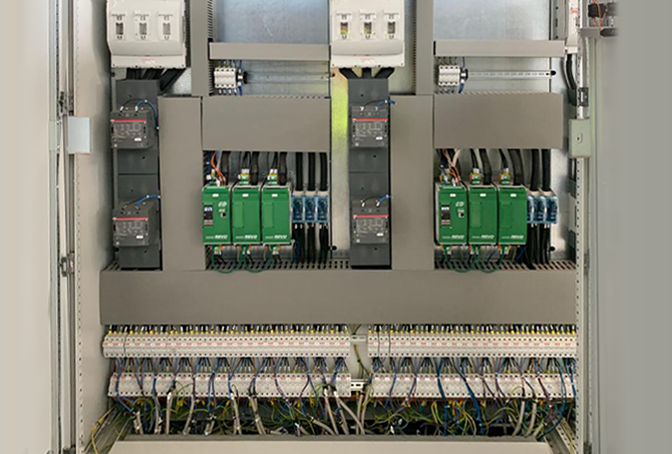

CD Automation can supply a complete panel comprising thyristor unit and temperature or humidity controller with automatic/manual control. The temperature can be measured with a thermocouple or pyrometer; in addition, a speed input can be used as a setpoint for the power.

Infrared lamps: some of the main applications

Explore how CD Automation’s products enhance the use of IR lamps in a variety of industries, offering customised solutions to optimise efficiency and performance in diverse industrial applications.

Paint drying

Infrared lamps are essential tools in the paint drying process, especially in industrial environments where speed and efficiency are crucial. In this context, CD Automation products emerge as ideal solutions. Thanks to their advanced control technology, CD Automation devices such as the REVO family of controllers, and in particular the REVO PN, allow the power emitted by infrared lamps to be precisely regulated. This precise control is crucial to ensure even and fast drying of the paint, avoiding problems such as overheating or poor curing. In addition, the efficient use of energy helps to reduce operating costs and environmental impact. With CD Automation’s products, operators can expect a paint drying process that is more controlled, efficient and adaptable to the specific needs of their industry.

Stretch Blow Moulding

In the stretch-blow moulding process, an area where precision and efficiency are essential, the integration of CD Automation products can lead to a significant improvement in machine performance. Power controllers such as CD Automation’s REVO family offer advanced temperature and power management, key elements in ensuring quality in the stretch blowing process. This precise heat regulation allows the optimisation of the plastic moulding process, while reducing cycle times and increasing the quality of the finished product. Furthermore, the energy efficiency achieved with these control systems not only reduces operating costs, but also contributes to the sustainability of the entire production process. The use of CD Automation products in stretch blow-moulding is therefore a strategic investment to increase efficiency and quality in this industrial application.

Other industrial applications using infrared emitters

- Thermoforming

- IR Platens

- Packaging

- Composites

- Coatings

- Glass Forming

- Oil industry

- Aerospace/Aviation

- Automotive

- Construction

- Food

- Photovoltaics/li>

- Printed Electronics

- Textiles

- Wood

Types of Infrared

- short waveform: peak current about 7 times nominal current. Attention must be payed in sizing the thyristors

- ultrashort waveform: peak current about 16 times nominal current. Attention must be payed in sizing the thyristors

- medium waveform: peak current equal to nominal current. No attention must be payed to peak current

- fast medium waveform: these elements are in thungsten like short type and the peak current is lower but the necessary time to be heated is longer and this stresses the thyristors

- long waveform: peak current equal to nominal current. No attention must be payed in sizing the thyristors

- In car industry and in other special applications the short IRW are supplied with very low voltage compared with the nominal one to change the IRW penetration. Cure must be used for these applications for current sizing of thyristors. In fact, must be used the normal precaution for short waveform plus extra precaution for voltage supply lower than the nominal that causes a lower peak but a very long overcurrent that stresses the thyristors. For sizing contact CD Automation, it will be necessary to collect more informations from the supplier of the IRW short.